- 20212021Power split gearbox TPV

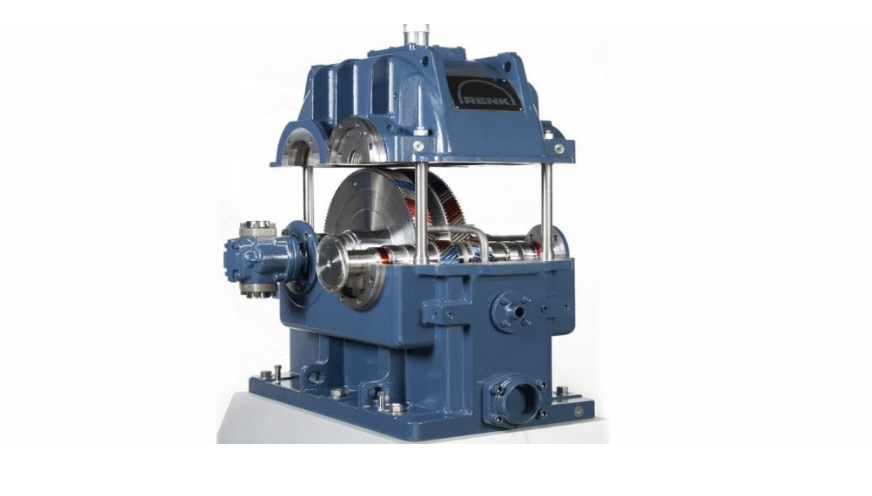

Power split gearbox TPV

Power split gearbox TPVRenk Turbo Transmissions

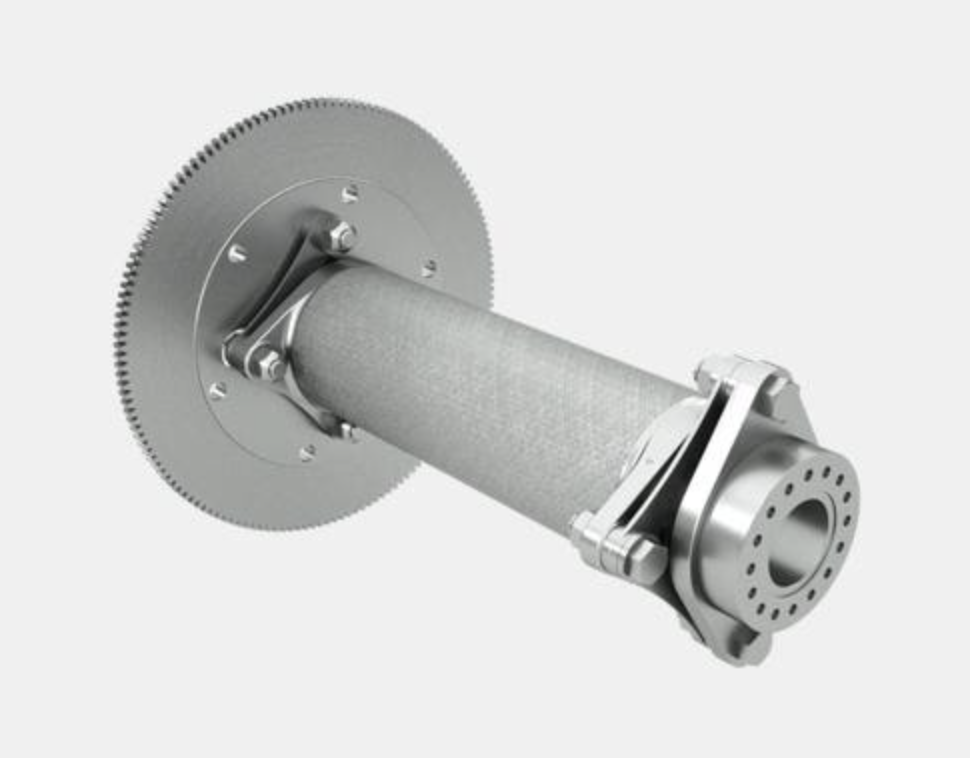

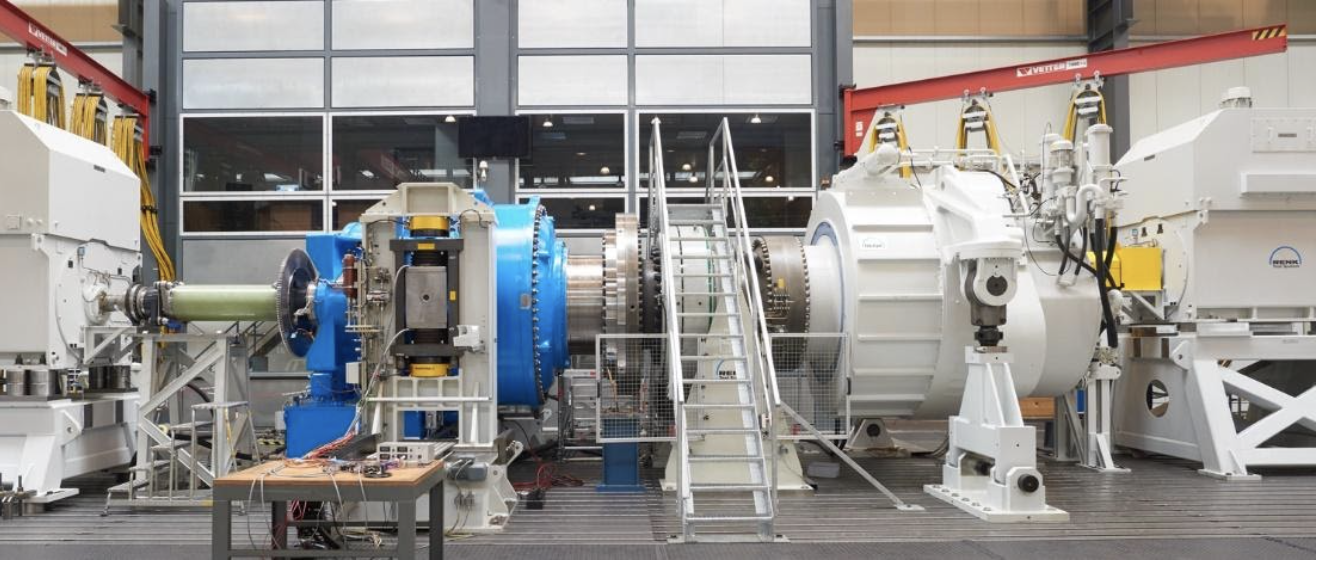

Spur GearPower split gearbox TPV

When extreme technical requirements exceed the usual limits of spur gears or planetary gears, this two-stage high-performance gear concept is used. Power split gearboxes allow the transmission of high power at the highest speeds of the input and output shafts with the least possible space requirement.

The input and output are aligned and have the same direction of rotation. Due to the free adjustability of all gears, an even load distribution is achieved. The unsupported high-speed pinion is guided over the meshing. With this technology, outputs of up to 200 MW and speeds of up to 120,000 rpm can be achieved.

The main feature of these Renk turbo gears are the case-hardened and highly precisely machined tooth flanks, which are designed for API, AGMA, DIN and ISO depending on the application. Detailed rotor dynamics calculations of all operating points are the basis of every design. Accordingly, our radial and axial bearing geometries are precisely optimized for the respective application and the operating conditions.Characteristics:

– Coaxial arrangement with the same direction of rotation

– Extreme transmission performance

– Compact design

– Low peripheral speeds

– Low mass movement

– Integrated couplings possible

– Compensation of thermal axial forces

– Attachment of oil pump or rotary drive possible

– Conservative gear design according to API 613 possibleFor more information, contact our sales team at info@azhollinkgroup.com

- 20212021TS / TB / TL plain bearing gear units

TS / TB / TL plain bearing gear units

TS / TB / TL plain bearing gear unitsRenk Turbo Transmissions

Spur Gear

TS / TB / TL plain bearing gear units

Based on many years of experience and the use of the most modern design and analysis tools, an optimized program of high-performance plain bearing gearboxes tailored to a wide range of applications was created. Gearboxes of this series are available with center distances from 355 to 1300 mm. 14 graduated sizes with 3 overall widths enable an optimal selection for these applications.

The plain bearing gear units of type group TS / TB / TL are designed according to customer requirements according to the guidelines of DIN, AGMA, ISO or API. The gearboxes can be equipped with the necessary instrumentation for temperature and vibration monitoring. Explosion protection requirements are also considered if necessary.

All pinion shafts and large gears are usually made of alloyed, highly wear-resistant case-hardened steel. The single or double helical teeth are case-hardened and ground. The tooth geometry is optimized according to the respective application and the running parameters.

Radial plain bearings that are optimized in terms of efficiency, oil consumption, stability behavior and reliability are used for the shaft bearings. Depending on the customer’s system concept, the gear unit can be equipped with an axial bearing on the wheel or pinion shaft. The axial bearing is integrated in the radial bearing as standard, but it can also be designed as a separate axial bearing. The installation / attachment of a mechanically driven oil pump, a rotor turning device, or a backstop is also possible.Characteristics:

– Application-specific adaptable translation to the point

– Speeds up to 80,000 rpm

– Translation up to 15 times in one-step execution

– Output up to 120 MW

– Short delivery times due to high stock levels

– Easy to maintainFor more information, contact our sales team at info@azhollinkgroup.com

- 20212021Renk Turbo Transmissions Spur Gear

Renk Turbo Transmissions Spur Gear

Renk Turbo Transmissions Spur GearRenk Turbo Transmissions

Spur GearTNA-TNB plain bearing gear units

The plain bearing gear units of the type TNA and TNB are the result of constant further development in the product area of our high-speed drive elements. This series, which RENK has had very successfully in its range since the mid-1980s, has now undergone an extensive makeover.

On the basis of many years of experience and the use of the most modern design and analysis tools, an optimized program of high-performance plain bearing gearboxes tailored to a wide range of applications was created. Gearboxes of this series are available with center distances of 200 to 560 mm. 8 sizes each in 2 different widths allow an optimal selection for these applications.

The plain bearing gear units of the TCS type group are designed in accordance with customer requirements in accordance with the guidelines of DIN, AGMA, ISO or API. The gearboxes can be equipped with the necessary instrumentation for temperature and vibration monitoring. Explosion protection requirements are also taken into account if necessary.

All pinion shafts and large gears are usually made of alloyed, highly wear-resistant case-hardened steel. The teeth are case-hardened and ground. The tooth geometry is optimized according to the respective application and the running parameters.

Radial plain bearings that are optimized in terms of efficiency, oil consumption, stability behavior and reliability are used for the shaft bearings. Depending on the customer’s system concept, the gear unit can be equipped with an axial bearing on the wheel or pinion shaft. The axial bearing is integrated in the radial bearing as standard, but it can also be designed as a separate axial bearing. The installation / attachment of a mechanically driven oil pump, a rotor turning device or a backstop is also possible.Characteristics:

– Application-specific adaptable translation to the point

– Speeds up to 15,000 rpm

– Translation up to 8 times in one-step execution

– Output up to 15 MW

– Easy to maintainFor more information, contact our sales team at info@azhollinkgroup.com

- 20212021Renk Turbo Transmissions

Renk Turbo Transmissions

Renk Turbo TransmissionsRenk Turbo Transmissions

Spur GearTCS plain bearing gear unit

The plain bearing gear units of the TCS type group are the result of a targeted development for applications in the field of high-speed compressor applications. After continuous further development, this series has also been used very successfully in turbine applications for years.

On the basis of many years of experience and the use of the most modern design and analysis tools, an optimized program of high-performance plain bearing gearboxes tailored to a wide range of applications was created. Gearboxes of this series are available with center distances of 400 to 1000 mm. 9 different sizes enable an optimal selection for these applications.

The plain bearing gear units of the TCS type group are designed in accordance with customer requirements in accordance with the guidelines of DIN, AGMA, ISO or API. The gearboxes can be equipped with the necessary instrumentation for temperature and vibration monitoring. Explosion protection requirements are also taken into account if necessary.

All pinion shafts and large gears are usually made of alloyed, highly wear-resistant case-hardened steel. The teeth are case-hardened and ground. The tooth geometry is optimized according to the respective application and the running parameters.

Radial plain bearings that are optimized in terms of efficiency, oil consumption, stability behavior and reliability are used for the shaft bearings. Depending on the customer’s system concept, the gear unit can be equipped with an axial bearing on the wheel or pinion shaft. The axial bearing is integrated in the radial bearing as standard, but it can also be designed as a separate axial bearing. The installation / attachment of a mechanically driven oil pump, a rotor turning device or a backstop is also possible.Characteristics:

Standard turbo transmission for the highest gear ratios in compressor and turbine systems, in which the drive and driven machine speeds have to be matched to one another

Realization of infinitely adjustable individual ratios at a speed of up to 27,000 rpm, a ratio of up to 15 times and an output of up to 20MW to customer-specific requirements

Very short response time for complete and individual components due to a high degree of size-specific standardization and the possible provision of intermediate products

Standard turbo gearboxes for all applications

Easy to maintainFor more information, contact our sales team at info@azhollinkgroup.com

- 20212021Renk Turbo Transmissions

Renk Turbo Transmissions

Renk Turbo TransmissionsRenk Turbo Transmissions

Spur GearTA..I – standardized API 613 gear concept

API gear design with fixed center distances and pre-engineered standard for the highest demands.For years, our innovative turbo gears have been ensuring steadily increasing efficiency in energy generation and process technology. The TAI series was specially designed for the special requirements of engineering in the oil & gas sector. This is a standardized, single-stage gear concept for high-speed applications. This type of gear unit is available in 6 housing sizes with fixed center distances. Power: up to 20 MW High speeds: <15,000 rpm Innovations from RENK have almost halved the power loss of turbo gear units in the past 20 years and have made a significant contribution to our customers being able to significantly increase the profitability of their systems. The main features of these RENK turbo gears are the case-hardened and highly precisely machined tooth flanks, which are designed for API, AGMA, DIN and ISO depending on the application. Detailed rotor dynamics calculations of all operating points are the basis of every design. Accordingly, our radial and axial bearing geometries are precisely optimized for the respective application and the operating conditions. Characteristics: - Welded construction - adaptable to specifications / customer requests - Short shaft overhangs for the best rotor dynamic vibration behavior - Best possible conventionally achievable efficiency - Optimized tooth geometry in terms of efficiency, noise and vibration excitations - Individually calculated optimal bearing geometries for every application - Excellent price / performance ratio - Short delivery time due to high stock levels - Variably selectable oil drain - Suitable for absorbing axial forces For more information, contact our sales team at info@azhollinkgroup.com

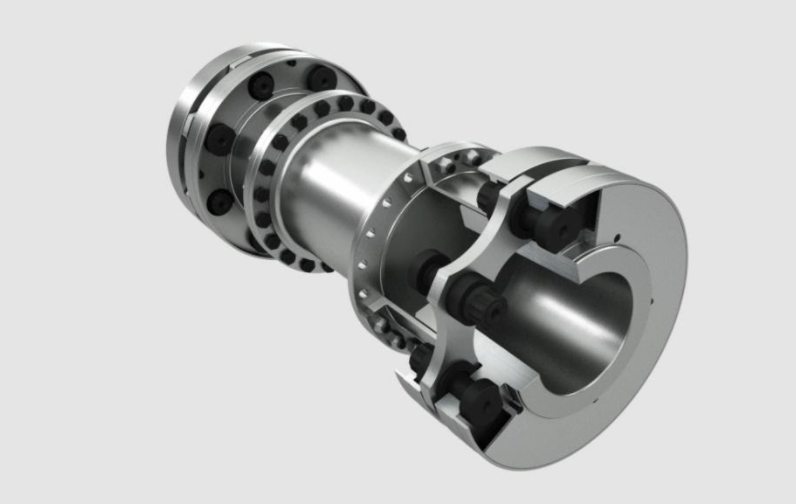

- 20212021RENK Gear Couplings

RENK Gear Couplings

RENK Gear CouplingsRENK Gear Couplings

The range of gear couplings from RENK has become the most comprehensive in the world since it was patented in 1939. The wide range of product series and versions gives you a high degree of freedom to design the shaft connections – also in the most demanding of applications.

Turbo series (Type TSB, TF, ZT)

The gear couplings in the turbo series are ideal solutions for transmitting high torques at maximum speeds.Features:

– For high and maximum speeds.

– Hardened and ground internal and external toothing for the ZT series.

– API 671-compliant, ATEX 2014/34/EU possible.For more information, contact our sales team at info@azhollinkgroup.com

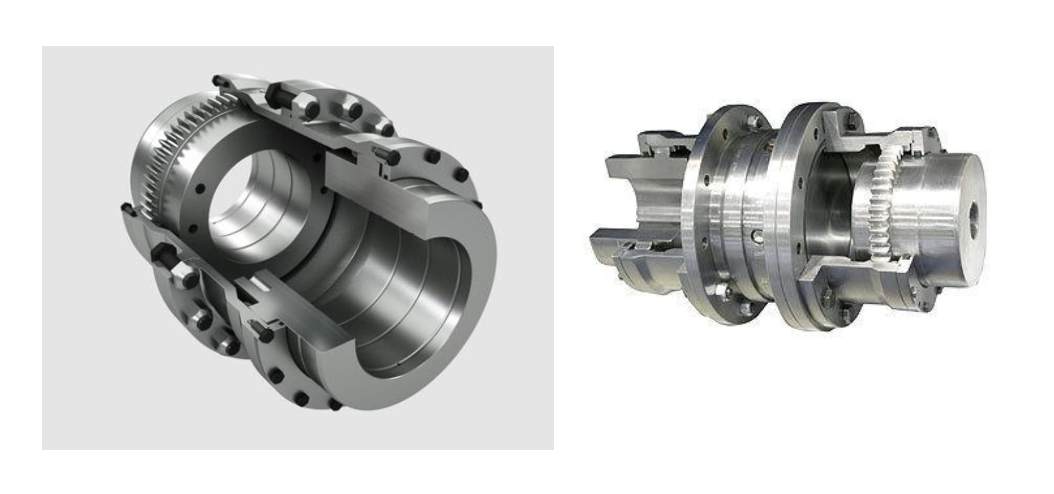

- 20212021Shifting Gear Couplings

Shifting Gear Couplings

Shifting Gear CouplingsShifting Gear Couplings

Connectable couplings (Type HAW) usually have a dual-cardanic design.

The gearing parts of the connectable gear coupling can be engaged or disengaged at a standstill or, for special designs, even in the event of synchronous operation of connected units. If necessary, operators can thus temporarily disconnect certain machines of a drive train or also connect auxiliary or alternative drives, if necessary.

For more information, contact our sales team at info@azhollinkgroup.com

- 20212021RAFLEX Flexible Disc Couplings

RAFLEX Flexible Disc Couplings

RAFLEX Flexible Disc CouplingsRAFLEX Flexible Disc Couplings

The low-maintenance, wear-free RAFLEX flexible disc couplings are torsionally rigid and flexibly offset. Due to the layered structure of the specially shaped discs, these couplings compensate for axial, radial, and angular misalignments between the drive and working machines without generating high restoring forces.

Standard and turbo series

(Type DSL, DSH, DSP, DTL, DTM, DTR, MT)Our RAFLEX portfolio is divided into two series: basic and turbo. The couplings in the DS series are particularly suitable for industrial use in pumps, fans, presses, crane systems, generators as well as for naval applications. The DT series is designed for high-speed applications such as turbines, compressors or generators.

Features:

– Backlash-free transmission of torque

– Compensation of shaft misalignments

– High quality in terms of run-out and balancing

– API-compliant, ATEX 2014/34/EU possible

– Maintenance-freeFor more information, contact our sales team at info@azhollinkgroup.com

- 20212021Renk Turbo Transmissions

Renk Turbo Transmissions

Renk Turbo TransmissionsRenk Turbo Transmissions

Renk Planetary Gear

COPAZ – freestanding compact planetary gear

Planetary gears have been an important part of the RENK product range for decades. RENK planetary gears transmit outputs of more than 20 MW and torques of more than 4.5 million Nm.

Thanks to their optimized designs combined with high manufacturing quality, they prove themselves particularly in long-term operation and thus ensure the availability of the system over long periods of time. At COPAZ, RENK uses a 3-dimensionally corrected straight high gear with great success. The sun pinion and planet carrier are case-hardened and ground, the ring gear is highly tempered, optionally hardened and precision-ground.

The transmission is free-standing, the high-speed clutch is included in the scope of delivery.The uncomplicated structure of COPAZ, the high manufacturing quality and the excellent efficiency guarantee low life cycle costs. The gearbox is preferably used in turbine systems for power generation as well as in process technology.

Characteristics:

– Most cost-effective free-standing gear solution

– little need for space

– Light weight

– Integrated HSS couplings & coupling casing

– No system-related internal axial forces

– Compensation of thermal external axial forces possible

– Coaxial shaft arrangement (no center distance)

– Reduced noise emissions due to the double-walled housing

– High efficiencyFor more information, contact our sales team at info@azhollinkgroup.com

- 20212021HYGUARD Safety Couplings

HYGUARD Safety Couplings

HYGUARD Safety CouplingsHYGUARD Safety Couplings

The HYGUARD safety coupling is a load-separating, torque limiting coupling that ensures an overload protection of high-quality components in the drive train. It transmits the torque via hydraulically generated frictional engagement. The release torque can be adjusted and remains constant throughout the entire operating time. Series (Type BW, BWL, HW, HEW, HDW) In addition to the standard series, variable adjustments can be made to customer requirements.

Features:

– Transmission of high torque in the smallest of spaces.

– Overload protection with adjustable constant torque limits.

– Constant trigger torque.

– Rapid recommissioning at minimal costs.For more information, contact our sales team at info@azhollinkgroup.com

- 20212021Hydro Power Slide Bearing Gear Units

Hydro Power Slide Bearing Gear Units

Hydro Power Slide Bearing Gear UnitsIndustrial Gear Units

Hydro Power Slide Bearing Gear Units

RIVThe slide bearing gear units of the RIV type group are the result of targeted standardization and development for applications in the field of power production via hydropower in the paper industry. This series has been very successfully employed in vertical Kaplan turbine systems thanks to continuous further developments since 1985. An optimized series of high-performance industrial gear units tailored to a broad range of applications was created based on many years of experience and incorporating the latest design and analysis tools. Gear units in this series are available with center distances from 500 to 1,500 mm.

Fifteen graduated sizes enable an optimal selection for these application scenarios. All pinion shafts and gear wheels are made of alloyed, highly wear-resistant case-hardened steel. Designed to be highly dependable, the toothing is ground and case-hardened. The gear geometry is optimized according to the respective application scenario and the running parameters.

Finely optimized radial slide bearings are used for the shaft bearings. A separate axial slide bearing with heavy axial stop collars is used as the axial bearing of the wheel shaft in the standard version. The adjusting device of the turbine can be routed through the wheel shaft. The gear unit is equipped with its own lubricant system, which contains all the required pumps, coolers, filters, and monitoring instruments. Hydrostatic jacking is available as an option in the slide bearings.Features:

– Application-specific, adaptable transmission to the point

– High degree of standardization across the various sizes

– Very short response time for complete and individual components enables the provision of intermediate product.

– Up to 15-fold transmission in single-stage version

– Maintenance-friendlyFor more information, contact our sales team at info@azhollinkgroup.com

- 20212021Hydro Power Planetary Gear Units

Hydro Power Planetary Gear Units

Hydro Power Planetary Gear UnitsIndustrial Gear Units

Hydro Power Planetary Gear Units

PAR/PBRPlanetary gear units have been an important part of RENK’s product portfolio for many decades. RENK’s planetary gear units transmit outputs of more than 30 MW and torques of more than 4.5 million Nm.

PAR/PBR planetary gear units are primarily used in the drive trains of Kaplan turbines. Their compact construction, even at high transmissions, permits a narrow turbine train with generators of very small sizes. The axial forces resulting from the operation of the turbines are absorbed by an oil-filled tilting pad bearing in the gear unit and conducted into the base via the housing. The individual segments can be inspected and/or replaced without disassembling the gear unit.

All the components are designed for permanent, wear-free operation with gearing of the highest quality and a correspondingly long service life. The use of the gear units enables the deployment of fast-running generators with a small air gap. Despite the unavoidable gear efficiencies, the efficiency of the power station is improved by approximately 1% through the use of gear units.Characteristics:

– Compact, extremely lightweight design

– Integrated high-speed couplings and coupling guards.

– Integrated axial bearing for absorbing turbine forces.

– Compensation of external thermal axial forces

– Co-axial shaft arrangement (no center distance)

– Low noise emissions due to double-walled housing

– Highly efficient, even during partial-load operation

– Optionally available in a flange version (no base)

– Operation between idling and full load possible

– Wear-free slide bearings

– Design with through bore for blade adjustment optionally availableFor more information, contact our sales team at info@azhollinkgroup.com

- 20212021RENK Gear Spindles

RENK Gear Spindles

RENK Gear SpindlesRENK gear spindles (Type GS) are primarily used where high torques need to be transmitted without a cardanic effect in conjunction with small external diameters. The design allows high misalignment compensation in combination with a high axial displacement. This is the case with hot and cold rolling mills, continuous casting systems, and straightening presses in particular.

Features:

High transmission of torque.

Compact external dimensions.

Large axial displacement and angular misalignment ± 3°.

Either grease or oil lubrication.

Customized design possible.For more information, contact our sales team at info@azhollinkgroup.com

- 20212021Renk Gear Tooth Joints

Renk Gear Tooth Joints

Renk Gear Tooth JointsRenk Gear Tooth Joints

As a connecting element between the drive unit and the hoist, for example in a crane lifting plant, curved tooth joints have a double function. In addition to the transmission of the torque, the forces acting radially on the drum are supported by the joint. The articulated connection is torsionally rigid, but flexible on all sides, which offers considerable advantages over a rigid coupling.

The curved tooth joint ® consists of the coupling hub with milled curved toothing, which engages in the coupling housing with butted internal straight toothing. The clutch hub is firmly connected to the gear shaft. A cylindrical shaft seat with a keyway connection is common. Other connections, such as a shrink fit or splined shaft, are also possible. The transmittable torque as well as the maximum permissible transverse load can be increased by an additional hardened toothing.Curved tooth joints ® are mainly used in the field of lifting and conveyor technology in crane hoists and cable drum drives.

For more information, contact our sales team at info@azhollinkgroup.com

- 20212021RENK Gear Couplings

RENK Gear Couplings

RENK Gear CouplingsThe range of gear couplings from RENK has become the most comprehensive in the world since it was patented in 1939. The wide range of product series and versions gives you a high degree of freedom to design the shaft connections and the most demanding of applications.

Basic series (Type LBK, SBK, SB)The gear couplings are particularly suitable for compensating axial, radial and angular shaft misalignments as torsionally rigid shaft connections for form-fit torque transmissions.

Features:

– Misalignment of ± 1.5° for each half of the coupling, up to ± 3° in special versions.

– Toothing versions: naturally hard, hardened, or hardened and ground.

– Special requirements such as class approvals, API 671 conformity or ATEX 2014/34/EU possible.

– Lubrication with oil or grease filling or continuous oil lubrication is possible.

– Various configurations available to suit customer requirement.For more information, contact our sales team at info@azhollinkgroup.com

- 20212021EQ-Flex® Flexible Disc Couplings

EQ-Flex® Flexible Disc Couplings

EQ-Flex® Flexible Disc CouplingsEQ-Flex® ensures reliable transmission of the torque and guarantees torque limitation in the event of overload. Robust materials ensure a long service life in the most demanding environmental conditions.

EQ-Flex® steel multi-plate couplings consist of optimized, maintenance-free and wear-free components. They are designed for a complete system life even under the most demanding environmental conditions. Due to the layer structure of the specially shaped plates, these clutches compensate for axial, radial and angular misalignments between drive and driven machines without generating large restoring forces.

An innovative torque limiter gives the coupling decisive advantages in order to increase the availability of the system and to optimize maintenance costs. For the first time, the slipping torque can be readjusted within a few minutes without dismantling the clutch. With coaxial platform configurations in particular, the time-consuming dismantling of the pitch lines to readjust the clutch is no longer necessary.

For more information, contact our sales team at info@azhollinkgroup.com

- 20212021Industrial Gear Units

Industrial Gear Units

Industrial Gear UnitsAZ Hollink Benelux B.V

Wind Turbine Gear UnitMaximum reliability due to the optimal load distribution and slide bearing technology:

EQ-Gear® combines maximum power density with compact dimensions in a unique way.Operating conditions with different combinations of speed and torque place high requirements on gearboxes in wind power. Special materials as well as innovative coating methods ensure an optimal operation – even at extremely high pressures and very low speeds. An intelligent planetary bearing system ensures a uniform load distribution in the respective operating conditions and optimizes the meshing contact of the gears. The intelligent planetary bearing system in connection with the use of five planets maximizes the power density.

The EQ-Gear® is suitable both for low and medium speed platform configurations in a coaxial design as well as for the highspeed drive train with an axial offset generator connection. With the coaxial platform configuration, the wire required for the pitch control can easily be guided through the gear unit between the input shaft and output shaft. The unique wireless temperature monitoring ensures the remote maintenance of slide bearings as well as the optimized self-adjusting load distribution between the planetary stages. This results in an excellent overall system that is designed specifically for the drive train of the wind turbine: with a RENK coupling and a RENK condition monitoring system. Optionally, the entire system, including the electrical connection, can be simulated and validated.

Features:

– Optimal load distribution

– Certified as per IEC and GL directives

-Reduced weight and parts variety

– Maximum power density

– Intelligent state monitoringFor more information, contact our sales team at info@azhollinkgroup.com

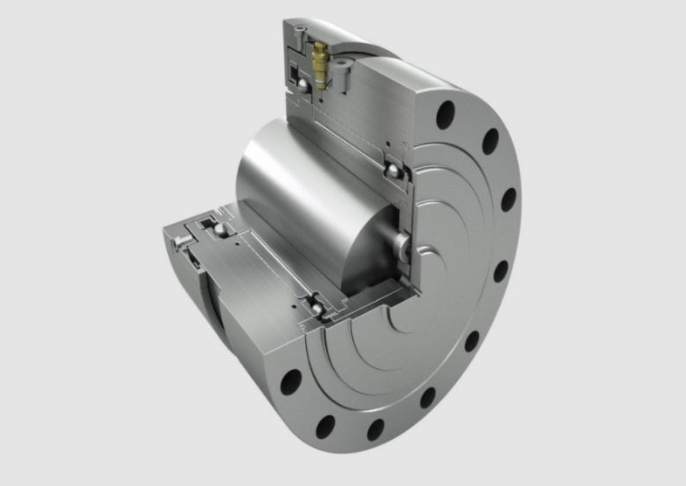

- 20212021Diaphragm Couplings

Diaphragm Couplings

Diaphragm CouplingsAZ Hollink Benelux B.V

Diaphragm CouplingsThe customized contour of the diaphragm allows for the compensation of axial, radial and angular misalignments under load.

Highest torques are safely and reliably transmitted at the highest speed via a contoured single or multi-disk diaphragm. Power ranges of up to 150 MW can be easily accommodated matching with our high speed gear units.

RENK diaphragm couplings are maintenance-free and stand out with their years of trouble-free operation. The basic design consists of just a few components. This makes assembly and handling easier for users.

Each diaphragm coupling is designed using FEM calculation methods to optimally meet the requirements of individual customers.Features:

– Maximum radial rigidity

– Low restoring and bending moments

– Lightweight

– Maximum balance quality

– Few individual parts

– Maintenance-free

– API 671-compliant, ATEX 2014/34/EU possibleFor more information, contact our sales team at info@azhollinkgroup.com

- 20202020AZ Hollink verhuist!

AZ Hollink verhuist!

AZ Hollink verhuist!Geachte relatie

Hierbij willen wij u informeren dat tussen 2 en 14 april, A.Z. Hollink stapsgewijs verhuist naar de nieuwe locatie in Apeldoorn.

Telefoonnummers en e-mailadressen blijven gelijk.

Ons bezoek- en postadres wordt:

Tweelingenlaan 63

7324 BK ApeldoornVanaf 14 april wordt het afleveradres:

Tweelingenlaan 69

7324 BK ApeldoornGelieve deze gegevens per direct in uw administratie aan te passen.

Let op: Vanwege de COVID-19 situatie trekt A.Z. Hollink twee weken uit voor deze verhuizing. Vanwege het advies van het RIVM is een bezoek aan onze vestiging niet mogelijk tot en met 4 Mei 2020.

A.Z. Hollink is geopend onze dienstverlening gaat ongestoord verder om de continuïteit van uw bedrijf te garanderen.Indien u vragen heeft of meer informatie wilt, kunt u contact opnemen met dhr. D.P.V Spillebeen.

Dit kan per mail op dieter.spillebeen@azhollinkgroup.com.

Of telefonisch via +31 6 83 52 91 11We would like to inform you that between 2 April and 14 April, AZ Hollink Benelux will be moving to a new location in Apeldoorn. Our telephone numbers and e-mail addresses remain the same. Our physical and postal address changes to the following:

Tweelingenlaan 63

7324 BK ApeldoornAs of 14 April, our delivery address is as follows:

Tweelingenlaan 69

7324 BK ApeldoornPlease update these details in your administration.

Please be advised that due to the coronavirus situation, we will be taking extra time to move as all safety and health measures need to be applied and adhered to. Visitors are not permitted at this time and as per the RIVM recommendations, this continues until 28 April 2020. We will however remain open and continue our services to our customers via e-mail/telephone etc.

Should you have any questions or need any further information, please do not hesitate to contact Mr. D.P.V Spillebeen via e-mail: dieter.spillebeen@azhollinkgroup.com or telephone: +31 6 83 52 91 11

- 20172017AZ Hollink breidt pakket verder uit!

AZ Hollink breidt pakket verder uit!

AZ Hollink breidt pakket verder uit!A.Z. Hollink transmissions uit Apeldoorn is voor de Benelux markt, een langdurige samenwerking aangegaan met ABB voor het importeurschap van Dodge. Met deze samenwerking voegt AZ Hollink een belangrijk product toe aan haar grote transmissie portfolio. Het grote voordeel van deze product range is de hoge kwaliteit van de gebruikte materialen en de Europese voorraad. Hierdoor kan er niet alleen een langere garantie worden afgegeven op het product, maar kan er ook sneller geleverd worden.

We geloven erin dat we met onze producten dichter bij de markt moeten zitten omdat de klanten vaak een 24 uurs service vragen.

Baldor-Dodge Raptor onderscheidt zich op de volgende punten:

- Makkelijk in onderhoud

- Op onderdeel niveau eenvoudig te vervangen

- Uitwisselbaar met concurrerende merken

- 5 jaar garantie ook op onderdeel niveau

- Snellere levertijd (EU voorraad)

Naast Baldor-Dodge is A.Z. Hollink transmissies ook distributeur van o.a. :

Renk, Stieber, Suco, Wichita, US Synthetic Bearings, Une, Warner, Schmidt-koppelingen, Huco en TB Woods. - 20172017AZ Hollink, Distribiteur van Kobelt

AZ Hollink, Distribiteur van Kobelt

AZ Hollink, Distribiteur van KobeltPer 1 juni 2017 wordt AZ Hollink de distribiteur van Kobelt industriële remmen in de Benelux. Kobelt is een Canadees productiebedrijf met meer dan 50 jaar ervaring in het ontwikkelen en produceren van high-end producten voor scheepvaart en industrie.

Met deze uitbreiding voegt AZ Hollink een zeer interessant product toe aan het leveringsprogramma. Kobelt onderscheidt zich onder meer door de toepassing van brons voor de remmen. Daardoor zijn deze uitstekend bestand tegen zuren en zouten. Daarnaast bieden ze een uitstekende prijs/kwaliteitsverhouding en lage onderhoudskosten als gevolg van goed bereikbare – en daardoor gemakkelijk en snel te vervangen – slijtdelen.

Veiligheid staat altijd voorop en de remmen van Kobelt bieden deze veiligheid. Eigen ontwikkeling en productie garanderen een hoge kwaliteit voor brede toepassing in de zwaarste industrieën. Ook zorgen ontwikkeling en productie onder één dak voor een grote flexibiliteit zodat probleemloos voldaan kan worden aan klant-specifieke eisen.

Als AZ Hollink zijn we trots dit prachtige merk te mogen vertegenwoordigen in de Benelux.

- 20172017Eems EXPO 14/15 juni 2017

Eems EXPO 14/15 juni 2017

Eems EXPO 14/15 juni 2017Bezoek AZ Hollink op de Eems Expo van 14 tot 15 juni 2017.

- 20172017AZ Hollink bij Ondernemend NederlandAZ Hollink bij Ondernemend Nederland

AZ Hollink is in de maand maart in het nieuws bij Ondernemend Nederland. Met het grote koppelingen pakket en de nieuwe innovatieve producten blijft AZ Hollink een belangrijke speler in de Aandrijftechniek.

- 20162016Importeurschap US Syntetics binnengehaald

Importeurschap US Syntetics binnengehaald

Importeurschap US Syntetics binnengehaaldHet Apeldoornse bedrijf European Transmission Company is de eerste in Europa die de hooggekwalificeerde diamantlagers van fabrikant US Synthetic aanbiedt. Het unieke van deze diamantlagers is dat ze geschikt zijn voor gebruik onder de meest extreme omstandigheden, waar normale lagers het zouden begeven. De diamantlagers worden vooral toegepast in de mijnbouw en de olie- en gasindustrie.

Toegevoegde waarde door innovatie

Rob Hendriks van European Transmission Company is trots op de Europese primeur: “Wij streven er als bedrijf altijd naar onze klanten toegevoegde waarde te bieden. Een van de middelen om dat te realiseren, is innovatie. Steeds betere ideeën creëren en betere producten aanbieden. Daar werken we elke dag aan. Het feit dat we nu deze unieke diamantlagers kunnen aanbieden, is daarvan weer een sterk voorbeeld.”Over European Transmission Company

European Transmission Company, opgericht in 2012, is onderdeel van de AZ Hollink Group, een internationale groep van bedrijven die gespecialiseerd zijn in mechanische aandrijftechniek. - 20132013European Transmission Company breidt haar aanbod uit met mot...European Transmission Company breidt haar aanbod uit met motoren, tandwielkasten en spindels

- 20132013Lancering van HITEX, High Quality Power Transmission Compone...Lancering van HITEX, High Quality Power Transmission Components en wereldwijde distributie van het merk

- 20122012Lancering webshopLancering webshop

- 20122012Oprichting Spear Marketing bvbaOprichting Spear Marketing bvba

- 20122012Oprichting van European Transmission Company B.V. met focus ...Oprichting van European Transmission Company B.V. met focus op de internationale aandrijfmarkt.

- 20122012A.Z. Hollink focust voortaan uitsluitend op het topsegment R...A.Z. Hollink focust voortaan uitsluitend op het topsegment RENK dankzij het toekennen van de importeurschappen in België, Nederland, Luxemburg, Frankrijk en Sub-Saharisch Afrika

- 20102010Oprichting van A.Z. Hollink South Africa (Pty) LtdOprichting van A.Z. Hollink South Africa (Pty) Ltd

- 20092009Groei van Europese importeurschappenGroei van Europese importeurschappen

- 20092009Nieuwe kantoren in ApeldoornNieuwe kantoren in Apeldoorn

- 20072007Exclusief importeur voor RENK Hannover in FrankrijkExclusief importeur voor RENK Hannover in Frankrijk

- Exclusief importeur voor RENK Hannover in FrankrijkExclusief importeur voor RENK Hannover in Frankrijk

- 20072007Exclusief importeur voor RENK Rheine in BelgiëExclusief importeur voor RENK Rheine in België

- 20072007Oprichting A.Z. Hollink Belgium bvbaOprichting A.Z. Hollink Belgium bvba

- 20062006A.Z. Hollink kijkt over de grenzen heen en zet de eerste sta...A.Z. Hollink kijkt over de grenzen heen en zet de eerste stappen in Belgie

- 20062006Exclusief importeurchap van RENK Hannover in BelgieExclusief importeurchap van RENK Hannover in Belgie

- Specialisatie in koppelingenSpecialisatie in koppelingen

- 20042004Naamswijzigning naar A.Z. Hollink B.V.Naamswijzigning naar A.Z. Hollink B.V.

- 20032003Verhuis naar een nieuw gebouw in DeventerVerhuis naar een nieuw gebouw in Deventer

- 20032003Overname Technisch Bureau HollinkOvername Technisch Bureau Hollink

- 20022002Overname van de wereldwijde distributie van de M-lagerOvername van de wereldwijde distributie van de M-lager

- 20022002De range van producten wordt uitgebreidDe range van producten wordt uitgebreid

- 19991999Verhuisd naar BaarnVerhuisd naar Baarn